COMPANY PROFILE / HISTORYCompany Profile, History

The purpose of Asano's business : “become an enterprise that pursues wealth and may be entrusted”.

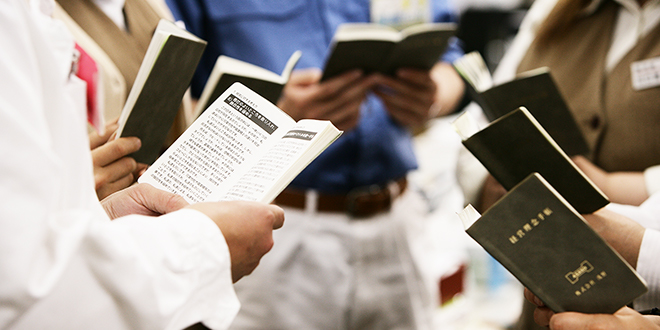

The management philosophy of Asano is “become an enterprise that pursues wealth and may be entrusted”. The so-called “pursue wealth”, not only means economic wealth, but the pursuit of spiritual wealth of survival value and work value by providing services for the clients. In addition to the client’s wealth, we also pursue the wealth of our business partners, regional society and our own.

In order to pursue wealth, we must go beyond our the clients expectations continuously, become an “enterprise that may be entrusted” by the clients, customers and regional society. Asano utilizes three tools to realize “management by all”. Those are “Small, organized units divisional accounting system”, “Business Plan” “Management philosophy book”, and all members share the information, combine their efforts to realize the management philosophy “become an enterprise that pursues wealth and may be entrusted”. This is the purpose of Asano's business. Asano always provides products and technologies beyond the clients’ expectations by implementing client-first thoroughly, exercising technologies continuously, is to realize the management philosophy “become an enterprise that pursues wealth and may be entrusted”

Company Profile

| Company Name | Asano Co.,Ltd. |

|---|---|

| Established | June 19, 1953 |

| Capital | 90 million YEN |

| Employees | 252 (from April 3, 2023 till now) |

| Management Philosophy | " Pursuing wealth and becoming a company everyone is dreaming of " |

| Business Scope | Product development supporting and production preparation supporting Business range: trial sheet metal parts production (trial stamping dies – trial sheet metal parts production – assembly), trial pipe processing, machine tool processing, fixture design and production, mass-produced sheet metal parts production, mass-produced stamping die production, injection precision mould production, mould design, CAD design, CAE analysis, simulation, shape measurement, reverse engineering, development of other products and supporting services in production preparation. |

| Business Office | Head office, Gunma factory(The First Metal Division) Production of prototype sheet metal parts(metal mold to product and assembly); machining, design and production of jigs, 3-D CAD design, simulation, shape measurement, reverse engineering, welding, assembly, pipe processing, hand-work, Design and production of press metal molds and jigs for mass production. Shizuoka factory(The Second Metal Division) Trial sheet metal parts production (moulds– products and assembly), mass-produced parts production, mass-produced mould production and shape measurement. Kyoto Factory (Resin Division SERA) Design and production of resin moulds and small-scale production of resin products. |

| Affiliated Companies | Zerocreate co.Ltd., |

Management System

■Head office, Gunma factory(The First Metal Division)

JIS Q 9001(ISO 9001)

JIS Q 14001(ISO 14001)

■Shizuoka factory(The Second Metal Division)

JIS Q 9001(ISO 9001)

JIS Q 14001(ISO 14001)

■Kyoto Factory (Resin Division SERA)

JIS Q 9001(ISO 9001)

JIS Q 14001(ISO 14001)

Company history

| 1945 | Enzo Asano founds ASANO Welders | |

|---|---|---|

| 1953 | Reorganized company organization and Asano Kogyo Co., Ltd. Was founded. Hideo Asano became the president. | |

| 1986 | Reorganized as Asano Industry Co., Ltd. | |

| 1987 | Headquarters factory completed (Sakai Higashi Arai, Isesaki City, Gunma Prefecture) | |

| 1992 | Company name was changed to Asano Co., Ltd. | |

| 1993 | Hideo Asano's eldest son Makoto is appointed to president | |

| 1997 | Shizuoka Factory established. Started Handling mass production press parts and mass production press dies. | |

| 1998 | Specialized company of CAD work (modeling, etc.), Makoto Co., Ltd., was established (Saitama City, Saitama Prefecture) | |

| 2001 | Makoto Co., Ltd was merged with Asano Co., Ltd. | |

| 2003 | Shizuoka factory qualified ISO9001: 2000 certification. | |

| 2004 | Resin Division SERA was established (Minami-ku, Kyoto City, Kyoto Prefecture) | |

| Jan. 2006 | Mold Division was established (Ota City, Gunma Prefecture) | |

| Aug. 2006 | Gunma Sanwa Factory was established (Sanwa-cho, Isesaki City, Gunma Prefecture) Shizuoka Factory was expanded | |

| Sep. 2006 | acquisition of patent for "injection mold" | |

| Jan. 2007 | “Integrated production technology for prototypes and small-quantity products” was qualified as “One Company One Technology” certification in Gunma prefecture. | |

| Apr. 2007 | Head Office / Metal First Division (Headquarters Gunma Factory / Gunma Sanwa Factory) was qualified ISO9001: 2000 certification. | |

| Sep. 2008 | Resin Division SERA was qualified ISO9001: 2000 certification. | |

| Apr. 2010 | Mold Division (Gunma Ota Factory) was merged into the 1st Metal Division. | |

| Jul. 2012 | 2012 Strategic Foundation Advancement Support Project adopted Plan name: "Development of molding technology for large in-vehicle products with thermoplastic CFRP" | |

| May. 2013 | Shizuoka factory was qualified ISO14001: 2004 certification. | |

| Jun. 2013 | Headquarters and Gunma Factory was relocated to Sanwa-cho,isesaki-shi. | |

| Aug. 2013 | Gunma Ota Factory(Mass production molds) was relocated to headquarters and Gunma Factory. | |

| May. 2015 | Headquarters and Gunma Factory was qualified ISO14001: 2004 certification. | |

| Oct. 2015 | Resin Division SERA was qualified ISO14001: 2005 certification. | |

| Nov. 2017 | JIS Q 9100: 2016 Quality management system-requirement for organizations in the aviation, space, and defense sectors Registered organization: Head Office / Gunma Factory Scope of registration: Manufacture of metal processed parts and press sheet metal processed parts for aerospace and defense equipment Manufacture of automotive molded parts using carbon fiber (Non-applicable clause: 8.3 Design and development of products and services) |