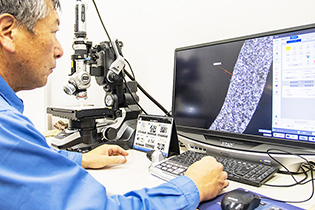

From the representative: Kuribara, Quality Assurance Division

At the Quality Assurance Division, we work every day under the slogan, "Don't have them make things, don't accept things, and don't let things slide".

We handle measurements in all fields: accuracy checks with articulated 3D measuring machine mainly for automobile and motorcycle parts; non-contact measurements with 3D models; measuring precision sheet metal parts and machined parts using portal 3D measuring machines; thin plate measurements with image measuring machines; etc.

To ensure welding quality, strength is checked with tensile and indentation tests. The welded parts are cut and macro confirmation is performed so that we only provide products that are guaranteed by reliable testing.

For hot stamping, we handle everything from press molding to complete. To guarantee the quality, tensile strength testing, hardness testing, and macro testing is performed.

With the introduction of ATOS, our range of measurements has been further expanded, allowing us to handle everything from single press to BIW.

For our customers, we have traceability management from order reception to shipment, and inspection data can be made available. Please feel free to get in touch with us.