From the representative: Funatsu, Complete Control Group

We respond to our customer's issues using a range of welding / joining techniques such as spot welding, MIG / MAG welding, TIG welding, laser welding, SPR, brazing, etc.

We handle welding and assembly of automobile frame parts and motorcycle parts using materials such as iron, aluminum, stainless steel, and titanium. We also propose solutions to the problems of our customers by actively incorporating next-generation welding equipment and joining technologies, such as robot welding and dissimilar metals bonding.

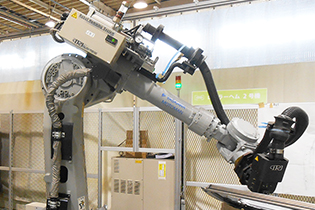

Using a spot welding line with two robots increases work efficiency and stabilizes welding quality. Automobile parts prototype assembly is handled by a system of robots.

*Photo is of a commercial vehicle

Handles brazing using disk lasers, scanner welding, and hybrid MIG welding.

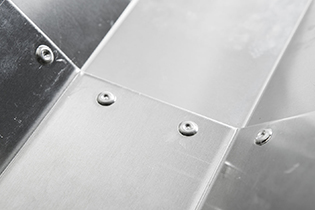

SPR is equipment for fastening materials of different strengths such as aluminum and high strength steel by press-fitting rivets. Prepared hole maching of the base metal is not required and spot-welding like high fastening strength is achieved.

A roller hemming robot system is used for joining automobile doors, hoods, and trunks, enabling high quality and reduced lead times. It can also be used for small-lot mass production.

Is prototype assembly under mass production conditions possible?

We respond to our customer's issues using a range of welding / joining techniques such as spot welding, MIG / MAG welding, TIG welding, laser welding, SPR, brazing, etc.