HEAD OFFICE / GUNMA FACTORYHead Office, Gunma Factory

Head office, Gunma factory produces prototype parts and press metal molds for mass production. We have a technology development department that develops new technologies and new products and an administration department that heads up all our operating divisions.

- Business Scope

-

・Prototype sheet metal parts: From molds to products and assembly

・Machining, round bar and pipe bending end processing

・Jig design and production. Injection molds to products

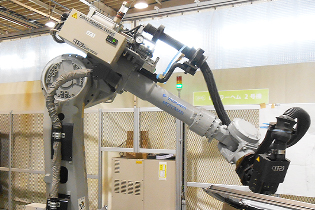

・Welding with guns and robots, assembly work, bending pipes and round bars, and associated assembly work

・Production of mass production press dies and jigs

Prototype Section

Prototype sheet metal section holds equipment for 3-D modeling from drawing data by CAD, casting of prototype mold by ZAS(zinc alloy), shaping processing and finishing by heavy machining center, sheet metal processing applicable to the various sizes by oil hydraulic press from 30-ton to 1200-ton, trimming processing by laser beam machine, welding, hand working, assembly, pipe processing, checking by 3-D measuring instrument and quality assurance , which are needed for the production of prototype sheet metal press parts and we produce in integrated production lines. In assembly, we have heavy spot welders that can process various shapes, robot welders, roller hemming processers, etc and we also have many welding technicians who are excellent in TIG welding that requires a great deal of skills. We have NC lathes , NC fraises and wire cut electric discharge machines and can machine resins and metals. At CAD section, we can do reverse engineering that makes 3-D data from various analyses and shape measured data with non-contact shape measuring instrument.

Press Metal Mold for mass production department

In press metal mold for mass production department, we produce metal molds for mass production such as single-shot type, transfer type, progressive type and jigs.

We design metal molds and analyze by making the best use of CAD and make a trial run with 1,000-ton mechanical press in-house.

We have good production performance of metal molds for mass production for body parts, function parts, intake and exhaust parts, seat parts for automobiles and outer parts and inner parts for motorcycles.

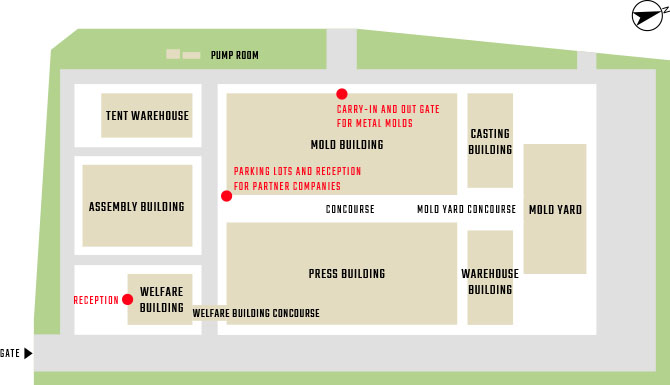

Layout

Location

2718-1, Sanwa‐cho, Isesaki City, Gunma, 372-0011 Japan

TEL 0270-75-1700

FAX 0270-75-1600

Owned equipment

2000t Hydraulic press

1000t Mechanical press

Hot press

ZAS casting

Spot welding robot system

Hemming robot system

Welding robot

Five-axis controlling machining center

| Classification | Name of machine | Manufacturer | Count | Remarks | |

|---|---|---|---|---|---|

| CAD CAM CAE |

File Server for CAD | IBM | 1 | Windows2008Server | |

| Client PC for CAD | HP | 25 | CATIA V5 | ||

| PC for CAD | common HD | 2 | 3DTascalX | ||

| PC for CAD | HP | 1 | ThinkDesign | ||

| PC for CAD | HP | 1 | GeomagicControl2015 | ||

| PC for CAD | HP | 1 | Polyworks2015 | ||

| PC for CAD | HP | 1 | RHINOCERROS5 | ||

| PC for CAD | HP | 1 | TOPsolid | ||

| PC for CAD | DELL | 1 | FAPTcuti | ||

| PC for CAD | HP | 1 | SOLIDWORKS Standard | ||

| VIEWER | common HD | 2 | DIPROVridgeR | ||

| VIEWER | common HD | 1 | JT2Go | ||

| PC for Press Forming Simulation | HP | 1 | AutoForm | ||

| PC for Press Forming Simulation | HP | 1 | JSTAMP | ||

| PC for Welding Simulation | DELL | 1 | Simufact Welding | ||

| PC for process schedule(C/S) | HP | 3 | FATs DNC | ||

| PC for CAM(MC) | DELL | 3 | WORK NC | ||

| PC for CAM(MC) | HP | 1 | PowerMILL | ||

| PC for simple structural analysis software | common HD | 1 | SOLIDWORKS Simulation Professional | ||

| PC for CAM(MC) | common HD | 2 | Nasuka | ||

| PC for CAM(MC) | common HD | 1 | TOPmold | ||

| PC for CAM(MC) | DELL | 1 | PC MULTI | ||

| PC for CAM(MC) | HP | 1 | Tebis | ||

| PC for CAM(LA) | HP | 1 | Tebis | ||

| PC for CAM(MC) | common HD | 2 | DELMIA | ||

| ZAS Casting | Zinc Alloy Melting Furnace | - | 1 | capacity 1.0ton | |

| Zinc Alloy Melting Furnace | - | 1 | capacity 1.5ton | ||

| Zinc Alloy Melting Furnace | - | 1 | capacity 3.0ton | ||

| Self-Hardening Casting Sand Kneader | Taiyo Machinery | 1 | Long Arm Mixer LAMA-5S 5ton/H | ||

| Machining Center | Double-Column 5-Face Precision MC | Shin Nihon Koki | 1 | RB-4N(4000×2000×600 (1100)) | |

| Double-Column 5-Face Precision MC | Mitsubishi Heavy Industries | 1 | MVR40(5000×3000×800 (1100)) | ||

| Double-Column 5-Face Precision MC | Mitsubishi Heavy Industries | 1 | MVR25(3000×1500×800 (1100)) | ||

| Double-Column 5-Face Precision MC | Mitsubishi Heavy Industries | 1 | MVR25Ex(3000×1500×800 (1100)) | ||

| Vertical-Type MC | OKK | 1 | VM7Ⅲ(1550×740 ×660) | ||

| Vertical-Type MC | OKK | 1 | VM-76R(1550×760 ×660) | ||

| Styrofoam-pattern-processing MC | Kikukawa | 1 | MC-713-1S(4000×2100(1100)) | ||

| Three-axis controlled MC | YCM | 1 | NMV106A(1020×600×600) | ||

| Three-axis controlled MC | YCM | 1 | NMV76A(762×510×560) | ||

| Five-axis controlled MC | Makino | 1 | V55-5XA(900×500×450) | ||

| Five-axis controlled MC | FANUC | 1 | αD21-MiB5ADVPLUS(200×200×200) | ||

| Shearing Band saw |

Shearing | Amada | 1 | H-1213(13mm MAX) | |

| Shearing | Amada | 1 | DCT2565(6.5mm MAX) | ||

| Shearing | Amada | 1 | DCT3065(6.5mm MAX) | ||

| Band saw | Amada | 1 | V400 | ||

| Band saw | TOKYO SHINDENKI | 1 | HT-10 | ||

| Band saw | Amada | 1 | V500 | ||

| Band saw for FMC | Kiyota-Koki | 2 | KY-600APH 600×600 | ||

| Band saw for FMC | Kiyota-Koki | 1 | KY-1000AP 600×1000 | ||

| Press Machine | Hydraulic Press | Kawasaki | 1 | 2000ton table5000×3000 stroke1700 | |

| Hydraulic Press | Kawasaki | 1 | 1200ton table3500×2500 stroke1500 | ||

| Hydraulic Press | Sanki | 1 | 1000ton table3500×2500 stroke1700 | ||

| Hydraulic Press | Kawasaki | 1 | 800ton table3500×2500 stroke1500 | ||

| Hydraulic Press | Sanki | 1 | 600ton table2500×1500 stroke1200 | ||

| Hydraulic Press | Sanki | 1 | 500ton table2000×1500 stroke1100 | ||

| Hydraulic Press | Sanki | 1 | 500ton table3000×2000 stroke1500 | ||

| Hydraulic Press | Kawasaki | 1 | 500ton table1800×1200 stroke1000 | ||

| Hydraulic Press | Sanki | 1 | 300ton table1600×1000 stroke750 | ||

| Servo Press | Aida | 1 | 300ton table1700×1200 stroke400 | ||

| Hydraulic Press | Sanki | 2 | 150ton table1000×1600 stroke750 | ||

| Hydraulic Press | Hydraulic | 1 | 150ton table1200×650 stroke500 | ||

| Hydraulic Press | Osaka-Jack | 1 | 100ton table1500×800 stroke300 | ||

| Hydraulic Break Press | Amada | 3 | 60ton table1000×440 stroke150 | ||

| Hydraulic Universal Press | Amada | 6 | 30ton table440×550 stroke100 | ||

| Norton Press | Amada | 1 | 50ton Deep Drawing Press table560×800 200 | ||

| Mechanical Press | Amada | 1 | 110ton | ||

| Hydraulic Press(CFR-1812-300FG) | Sanki | 1 | 300ton table1800×1200 stroke900 | ||

| Disk Puncher | Fujikikou | 1 | 30ton | ||

| Die Quench | Die Quench System with Automatic Loader |

AP&T | 1 | 3-step Heating Furnace, Maximum Material Size 2040×1600 |

|

| Heating Furnace for Die Quench | YAC DENKO | 1 | Maximum Material Size 1800×900 | ||

| Laser Processing |

3-D 5-axis Laser Processor | TRUMPF | 1 | TruLaser5030fiber 4.0KWh *Introduced in Nov. | |

| 2-D 3-axis Laser Processor | TRUMPF | 1 | TruLaser3030fiber 3.0KWh | ||

| 3-D 5-axis Laser Processor | Komatsu | 1 | 3.3KW (1900×3100×800) | ||

| 3-D 5-axis Laser Processor | Komatsu | 4 | 2.0KW (1900×3100×800) | ||

| 2-D 3-axis Laser Processor | Komatsu | 1 | 2.0KW (1500×3000×800) | ||

| Laser Marker | Keyence | 1 | YV4Laser Processible Area 120×120 | ||

| Former | Craft Former | Eckold | 1 | KF340 W680×L1215×H1760 | |

| Hand Former | Eckold | 1 | HF100 W390×L700×H960 | ||

| Caulking | Caulking Machine | Brother | 1 | BR2-121 | |

| Caulking Machine | HINO | 1 | 200V | ||

| Riveting Machine | Yoshikawa Iron | 1 | US-150 | ||

| Hemming | Roller Hemming Robot System | Try Engineering | 2 | RHS-300L(table2) | |

| Welding Machine |

Disk laser Welding Robot System ・Brazing welding ・Remote welding ・Aluminum Hybrid welding |

TRUMPF (laser oscillator) |

1 | TruDISK 6001 output:6kWh Robot:KUKA Brazing welding head:SCANSONIC AL0-3 coaxial head:TRUMPF D70 Remote welding head:TRUMPF PFO-3D Aluminum Hybrid welding head:FRONIUS |

|

| Spot Welder | Panasonic | 1 | 50kVA | ||

| Stationary Spot Welder | Dengensha | 2 | 35kVA | ||

| Stationary Spot Welder | Nasutoa | 1 | 60kVA | ||

| Stationary Spot Welder | Nasutoa | 1 | 125kVA | ||

| Stationary Spot Welder | Nasutoa | 2 | 150kVA | ||

| Argon Welder | Panasonic | 2 | 300A Tig | ||

| Argon Welder | Panasonic | 2 | YC-300BP2 | ||

| Argon Welder | Panasonic | 1 | 200A Tig | ||

| CO2 Welder | Panasonic | 6 | - | ||

| CO2 Welder | Daihen | 1 | - | ||

| Portable Arc Welder | Daihen | 1 | 250 | ||

| CMT Cold-Metal-Transfer Low Temperature Welder |

Fronius | 1 | 400A | ||

| CMT Welding Robot | Fanuc | 1 | Robot ARC mate 100iD CMT Fronius TPS/400i | ||

| Welding Robot | Yasukawa | 1 | - | ||

| Welding Robot | Panasonic | 1 | 350A | ||

| Welding Robot Plasma combined use | Panasonic | 1 | 3-D 6-axis Power500A Plasma350A | ||

| Welding Robot | Panasonic | 1 | 3-D 6-axis Power 450A | ||

| One-Jig Welding Robot | Panasonic | 3 | TAー1800WG3 | ||

| Spot Welding Robot System | Fanuc | 2 | RobotM-900i Traveling Type | ||

| Spot Welding Robot System | Fanuc | 4 | RobotR-2000iB/RobotR-2000iC | ||

| Spot Welding Robot System for car body |

Fanuc | 2 | RobotR-2000iC/210F | ||

| Three-Phase DC water cooling Spot Welder | Tecna | 1 | ART-3650 | ||

| Voltage Converter for Portable Spot Welder | Nasutoa | 1 | 180kVA | ||

| Voltage Converter for Portable Spot Welder | Denyo | 1 | 180kVA | ||

| X-shaped Spot Welding gun | Denyo | 4 | Reach500 500kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | Reach800 200kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | Reach800 500kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | Reach700 500kgf | ||

| X-shaped Spot Welding gun | Denyo | 2 | Reach400 500kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | Reach300 500kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | Reach300 200kgf | ||

| X-shaped Spot Welding gun | Denyo | 1 | - | ||

| C-type Welding Gun for Spot Welding | Denyo | 1 | Reach350 200kgf | ||

| C-type Welding Gun for Spot Welding | Denyo | 1 | Reach150 500kgf | ||

| C-type Welding Gun for Spot Welding | Denyo | 1 | - | ||

| Argon Welder | Panasonic | 4 | 300A | ||

| Argon Welder | Panasonic | 3 | 200A Mig | ||

| Mig Braze Welder | Panasonic | 1 | 350A | ||

| Welder | ARO | 1 | Reach800 16000A 400 | ||

| Servo Seam Welder | DENGENSHA TOA | 1 | RCG-155S 155KVA | ||

| Seam Welder | Aichi Sangyo | 1 | 48kVA | ||

| Spot Welder | Panasonic | 1 | 90kVA | ||

| Spot Welder | Panasonic | 2 | 50kVA | ||

| Spot Welder | Panasonic | 1 | 35kVA | ||

| Stationary Spot welder | Daihen | 1 | 95kVA | ||

| Portable Spot Welder for Aluminum | OBARA | 1 | Reach1000 150KVA | ||

| Plasma Cutting Machine | Panasonic | 1 | - | ||

| Vibro Shears | Horii | 1 | 3.2×φ1000m/m | ||

| TIG Welder | Panasonic | 2 | - | ||

| Stainbrite | TAIHOKOHZAI | 1 | - | ||

| Special Type Welding Machine | Toyoseiki | 1 | Heat MAX350℃ | ||

| STUD Welder | NIPPON POP RIVETS AND FASTENERS | 1 | DCE1800 Head゙PLM560 | ||

| Riveting | SPR System | NIPPON POP RIVETS AND FASTENERS | 1 | Reach600 | |

| Drilling Machine | Drilling machine | - | 9 | φ30 2013 | |

| Radial Drilling Machine | Ooya | 1 | RE-1000A | ||

| Radial Drilling Machine | KAO | 1 | KMR-1600DH | ||

| Tapping Machine | - | 4 | φ13 | ||

| Milling | NC Milling Machine | Shizuoka | 4 | 750×450×400 | |

| Lathe | Large NC Lathe | Yamazaki Mazak | 1 | NEXUS400-Ⅱ φ580 | |

| General-purpose Lathe | Takizawa Iron | 1 | 300×800 | ||

| General-purpose Lathe | Wasino | 1 | 500×860 | ||

| General-purpose Lathe | Wasino | 1 | LE-19K | ||

| NC Lathe | Hitachi | 1 | 190×320 | ||

| Hole Machine | NC Narrow Hole Machine | Sodick | 1 | 200×300×250 | |

| WEDM | Wire Electric Discharge Machining | Mitsubishi | 1 | MV4800 800×600×300 | |

| Wire Electric Discharge Machining | Fanuc | 1 | α-1ID 600×400×300 | ||

| Injection Molding Machine | Injection Molding Machine | Sumitomo | 1 | SE100EV 100ton | |

| Injection Molding Machine | Niigata | 1 | 100ton 250×250×100 at Mold Size | ||

| Grinder | Flat Surface Grinder | Okamoto | 1 | 800×600×250 | |

| Endmill Grinder | Sanyo | 1 | GE-120 Type | ||

| portable Grinder | Hitachi | 1 | 200V 3.5A | ||

| Belt Grinder | Shimomura | 1 | 200V | ||

| Polisher | Flat Surface Polisher | Wasino | 1 | 500×200 | |

| Others | Bench Lathe | Katsukura | 1 | 200×150 | |

| Bandsaw | Daito | 1 | S4560 up to φ450 Maximum capacity 620×450mm | ||

| Bandsaw | Nicotech | 2 | SCP-25SA up to φ300 | ||

| Drill Polisher | DAREX | 1 | V290 φ3~φ19 polishable | ||

| Bender | Amada | 1 | RG-35S | ||

| FINE CUT | Heiwa | 2 | - | ||

| Pipe processing | NC Pipe Bender | Taiyo | 1 | TR-DR-30CNC-HR | |

| CFRTP | Electromagnetic induction Heater | Roctool | 1 | 300KW | |

| Mold temperature controller | TECH HEIWA | 4 | 1ch(30A)×6Ch | ||

| Electric furnace | Hata Electric | 1 | ELEPOT 1300℃MAX・Φ620×650 | ||

| Perfect oven | ESPEC | 1 | 600×600×600 Max300℃ | ||

| Injection Equipment | NISSEI PLASTIC | 1 | IU50AN 200t | ||

| Abrasive Water Jet Cutter | SUGINO | 1 | Cutting range 2000×1500 Robot specifications | ||

| High Pressure Water Storage Tank for mold cooling | Todax | 1 | Impoundment 1500? Flow 400?/min | ||

| Vacuum Equipment | ULVAC | 1 | measuring range 0.4~3000Pa | ||

| Crane Hand Cart |

Overhead Crane | Nippon hoist | 1 | 15ton/7.5ton Parent and Child | |

| Overhead Crane | Nippon hoist | 7 | 10ton/5ton Parent and Child | ||

| Overhead Crane | Nippon hoist | 1 | 5ton/2.8t Parent and Child | ||

| Overhead Crane | Nippon hoist | 1 | 2.8ton | ||

| Single Leg Crane | Nippon hoist | 4 | 2.8ton | ||

| Jib Crane | Kito | 1 | 2.8ton | ||

| DC Battery Hand Cart | Nippon hoist | 1 | 25ton | ||

| Fork Lift | Fork Lift | NIssan Fork Lift | 1 | 7ton | |

| Fork Lift | NIssan Fork Lift | 1 | 4ton | ||

| Fork Lift | Sumitomo Fork Lift | 1 | 3.5ton | ||

| Fork Lift | Sumitomo Fork Lift | 2 | 2.5ton | ||

| Fork Lift | Sumitomo Fork Lift | 2 | 2.5ton electric | ||

| Fork Lift | unicarirriers | 1 | 3.0ton electric | ||

| Fork Lift | Toyota | 1 | 2.5ton | ||

| Reach ForkLift | Sumitomo Fork Lift | 1 | 1.8ton | ||

| Reach ForkLift | Sumitomo Fork Lift | 1 | 1.5ton | ||

| Measuring Equipment | 3D Measuring System | GOM | 1 | ATOS ScanBox 8260 | |

| 3-D Measuring Machine | Mitutoyo | 1 | CRT AS9106 (905×1005×605・RangeX,Y,Z) | ||

| Multi-joint Non-contact Measuring Machine | Faro Japan | 1 | Scan Rate:28scan/sec(640point/1sec)(13,400point/sec) | ||

| Multi-joint Measuring Machine(with shape measuring) | Hexagon Metrology | 4 | ROMA ABSOLUTE ARM 10ft 7axis arm | ||

| Multi-joint Measuring Machine(with shape measuring) | Hexagon Metrology | 2 | ROMA ABSOLUTE ARM 9ft | ||

| Multi-joint Measuring Machine(with shape measuring) | Hexagon Metrology | 1 | ROMA ABSOLUTE ARM 8325 7axis arm | ||

| 3-D Scanner Type 3-D Measuring Machine | Keyence | 1 | VL-500 | ||

| Contour Shape Measuring Machine | Mitutoyo | 1 | CV-3200 | ||

| Tension Tester | Aichi Sangyo | 1 | 50KN | ||

| Tension Tester | Aichi Sangyo | 1 | ART-5 50KN | ||

| Tension Tester | Shimazu | 1 | AG-100KN | ||

| Image Measuring Machine(Quick scope) | Mitutoyo | 1 | QS200 (200×250×100・RangeX,Y,Z) | ||

| Micrometer Scope | Keyence | 1 | VHX-500F (Mag.25~175) | ||

| Micrometer Scope | Keyence | 1 | VHX-5000 (Mag.20~2000) | ||

| Non-Destruction Spot Measuring Machine | Nadex | 1 | RSWA for Spot Nugget diameter measurement | ||

| Inner Micrometer | Mitutoyo | 1 | 3~28・5~30・25~50・75~100・100~125・125~150 | ||

| Inner Micrometer | Mitutoyo | 5 | 5~30・25~50・50~75・75~100 | ||

| Outer Micrometer | Mitutoyo | 1 | 0~25・25~50・50~75・75~100・61~150 | ||

| Outer Micrometer | Mitutoyo | 9 | 0~25・25~50・50~75・75~100 | ||

| Blade Micrometer | Mitutoyo | 2 | 0~25・25~50 | ||

| Point Micrometer | Mitutoyo | 2 | 0~25 | ||

| Outside Micrometer | Mitutoyo | 1 | 0~25・25~50 | ||

| Caliper | Mitutoyo | 1 | 10~22・20~32 | ||

| Surface tester | Mitutoyo | 1 | SJ210 | ||

| Protractor | - | 2 | - | ||

| Block Gauge | - | 1 | BMI―F112/1-0 t1.0~t100.0 | ||

| Block Gauge | Mitutoyo | 1 | BMI―F112/1-0 t1.0~t100.0 | ||

| Pin Gauge | - | 1 | 1.0~13.0(0.025step)13.0~19.0(0.1step) | ||

| Pin Gauge | - | 1 | 1.0~13.0(0.025step)13.0~19.0(0.1step) | ||

| Plug Gauge | - | 1 | 72 kinds | ||

| Feeler Gauge | Mitutoyo | 1 | 0~10 | ||

| Cylinder Gauge | Mitutoyo | 1 | 6~10・10~18・18~34・35~60 | ||

| Ring Gauge | - | 1 | 100 kinds | ||

| Master Ring | - | 1 | 20 kinds | ||

| Micro Vickers Hardness Tester | Marumoto Struers | 1 | Durascan-70 | ||

| Rockwell Hardness Tester | Mitutoyo | 1 | HR-400 | ||

| Dual Type Film Thickness Meter | Kett | 1 | LZ-370 | ||

| Fine Cutter | Marumoto Struers | 1 | Secotom50 | ||

| Automatic Resin Filling Machine | Marumoto Struers | 1 | CitoPress-1 | ||

| Automatic Cleaner | Marumoto Struers | 1 | Lavamin | ||

| Automatic Polisher | Marumoto Struers | 1 | Tegramine 25FC | ||

| Test Polisher | IMT | 1 | Rana3 φ250㎜ | ||

| Ultraminitured Thermal Image Sensor(Thermography) | Apiste | 1 | Measuring Range -40℃~500℃ | ||

| Digital Vernier Caliper | Mitutoyo | 9 | 100・150・200・300 | ||

| Vernier Caliper(including digital) | - | 33 | 150~1000 | ||

| Digital Height | - | 8 | 300~600 | ||

| Digital Height | Mitutoyo | 2 | 300・600 |

| Classification | Name of machine | Manufacturer | Count | Remarks | |

|---|---|---|---|---|---|

| Machining Center | Double column type MC | Okuma | 1 | MCV-AⅡ (4000×2000×1000) | |

| Double-Column 5-Face Precision MC | Okuma | 1 | MCR-A5CⅡ (4000×2000×1000) | ||

| Double-Column 5-Face Precision MC | Shinnihon Koki | 1 | RB-4VM (4000×2000×1200) | ||

| Milling Machine |

CNC Milling Machine | Okuma | 1 | 4V-NC (435×450×1300) | |

| Multi-Purpose Milling Machine | Osaka Kiko | 1 | MH-3V (650×1650) | ||

| Lathe | Lathe | Tsuda | 1 | TSL-1800 (1800×900×170) | |

| Grinder | Flat Surface Grinder | Nagase | 1 | SGW64 (300×600) | |

| Forming Grinder | Okamoto | 1 | Forming Grinder | ||

| drilling Machine | Radial Drilling Machine | Ikeda Koki | 1 | RMA-1300 (1300) | |

| Radial Drilling Machine | Otori Koki | 1 | BR-20 | ||

| Radial Drilling Machine | Ogawa | 1 | HOR-D1700 | ||

| Band Saw | Band Saw | Amada | 2 | V400 | |

| Welder | Electronic Welder | Osaka Denki | 3 | BZ-200F-3 | |

| Argon Welder | Panasonic | 1 | YC-300BZ3 | ||

| Argon Welder | Panasonic | 1 | PANA-TIG | ||

| Press | Mechanical Press | H&F | 1 | 1000ton table2200×3500 stroke800 | |

| Shearing | Shearing | Amada | 1 | MAX3.2mm | |

| CAD CAM CAE |

2-D CAD | Autodisk | 1 | Auto-CAD LT | |

| 3-D CAD/CAM | Nihon Unisys | 3 | CADmeister | ||

| 3-D CAM | Sesukuwa | 1 | Work NC | ||

| 2-D CAD CAM | Camtus | 1 | speedymill/win | ||

| CAD PC | Camtus | 1 | 3DTascalX | ||

| Others | Drill Polisher | Iida | 1 | YG-50 |