ASANO PRIDE AS A CRAFTSMAN VOL.4 : SHIGERU IMAIVol.4 SHIGERU IMAI

Spring of 2010 was the first time for him to travel in China together with his family. In autumn of this year, he got the changing department announcement. "Shigeru Imai, will be appointed to go to China to work in 2011". It can be unbelievable that I will work in China where I never dreaming to go.For the first business of Asano Company in China, the total of 5 Samurai (workers) including Imai are about to depart.

This way is also very interesting

Method of improving 20% work quality

Invited by his family members, he turned into resin mould industry. During the beginning period of breeding career, his father was ill and had to be in hospital for a long time. When his elder brother was to build a resin mould factory by himself, he turned into the mould industry under the invitation of his elder brother. From the world of fish to metal mould, it is a transformation of 180 degree. People around him all felt very unique. But up to now, Imai himself has been unwavering. Unexpectedly, after accepting OJT (on the job training) from his elder brother, he accumulated creative knowledge and just like a bibulous sponge, his knowledge about mould kept increasing.

All his family took part in the cooperation with ""Sera making institution"" which was the predecessor of Asano resin division SERA. When "Sera" is talked about, everybody knows that it's time-honored in the mould industry. It is said that there are also many people who separate themselves from Sera and build mould factories by themselves. Imai can turn into "Sera making institution", which is natural during the cooperation. In fact, up to now the son of his elder brother still works for the design department of resin division SERA. "Sometimes there are some calls, when asked, I find out that they are for my nephew," Imai said with a smile.

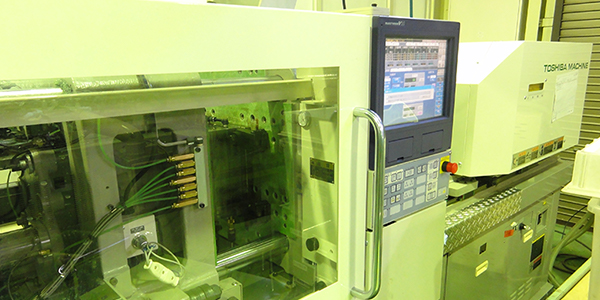

After entering into "Sera making institution", he faced new challenges. There were some cases when even the software for mechanical processing cannot be purchased. At that time, for one whole year, he learned BASIC*2 at the same time of working. In order to use Macro Program*3 to automatically calculate and cut 2.5 demension and 3 demension moulds with complex shapes, he developed software by himself. ""I am famous for being called a nagging person by the machinery manufacturer and supplier"", Imai said with a bitter smile. He made everything by himself, so he usually skipped the business department of manufacturers and contacted directly with the development department of the other party. "Just like making tests with litmus paper among technicians. You shouldn't give up even if the supplier rejects you. After discerning their potential of being capable, once I show the requirement, the technicians of the other party will live up to your expectation." Imai says so even now.

Imai, who enjoys manufacturing industry in the mould world, recently worries about something. That is to encourage young people's spirit on manufacturing industry. ""As long as you undertake technology, then you should hold on and practice technology in this society. In school you pay for practicing, but when you step into this society, you get wages, so you must practice by yourself and learn it by heart"" Imai says. Once he said it, he will practice it. After stepping into the mould world, he learned by himself and got the qualification certificate of level 1 supark machining mechanic*4. He overcame this national examination costing for one whole day, which must be the effort from the creative knowledge accumulated during everyday work.

When talking with young people, he has said like this. "If you do as the experienced worker tells you to, then you can only finish 80% of the work. This is normal, because you are not the experienced worker. That is to say, if you always do as the experienced worker tells you to, then 80% x 80% x and the finishing rate is smaller and smaller. When you add 40% of your effort to the 80% finishing rate, then you can get 20% more than what the experienced worker teaches you and in this way, you can make out good things".

You cannot always be off duty on time after finishing the work required by the company. If necessary, you should make use of some after-work time, and only in this way can you be qualified. Imai, who masters technology and gains payment through hard work in all his life, is a little worried. Because Imai, who liked fish from childhood, understands that it is important that we shouldn't be lazy and must work hard continuously. Imai himself is like this, so he also hopes that the young people can challenge all kinds of qualification certificates.

After "Sera making institution" was merged with Asano in 2004, Imai has been undertaking the resin mould in Kyoto up to now. "Is there any change after merging?", "Every kind of thing must be written, and even the calls must be recorded. At first, I didn't get used to it and felt bothered, but now I feel the importance of it. It's not oral constraint but written on the paper. It's to avoid inactive misunderstanding even in China with different cultures." Imai answers like this.