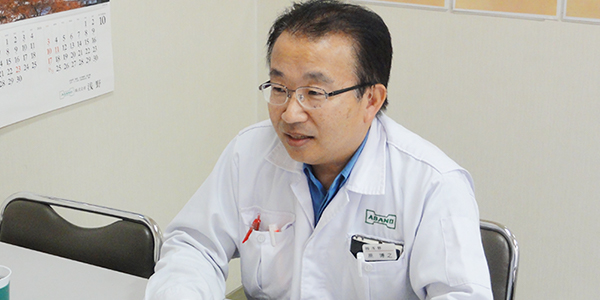

ASANO PRIDE AS A CRAFTSMAN VOL.3 : HIROYUKI HARAVol.3 HIROYUKI HARA

Hara has been devoted to quality assurance for twenty-one years. In Asano, nobody can be more qualified about quality assurance than Hara. As long as he takes a glance at the design drawing, he can understand the designer's mind. Calm eyes and way of speaking are the styles of quality assurance in Asano.

Excellent performance of the department is its duty

Carry on working hard on the job is their duty

“No news is good news"", which is one of the widely-used popular sayings in the world. It's also no exception to the quality assurance department. When there isn't any alter contact put forward by clients on our products, Hara will feel very consoled. “Excellent performance of the department is its duty"", Hara says so. It won't go too far to say that no contact from clients is the "equivalent meaning of satisfication."

When F1 auto trends Ayrton Senna da Silva was in full bloom, Hara was young and undertook the quality assurance of F1 relevant components. Hara recalled that he had watched F1 cycle racing at that time and when he saw the checkcred flag signing the final race waved in front of him, he suddenly felt relieved.

Undertaking the quality assurance for twenty-one years, Hara has always been growing up with the company. Therefore, he realized the importance of "comprehensive abilities".

Like most of the companies in the world, as the company continues to expand its scale, its specialization is higher and higher. There is no exception to the Asano. Through function divisions such as punch press responsible for stamping process and laser cutting responsible for laser material processing, etc, the young workers are nurtured into experts. At the same time, Hara realizes that seen from the whole product balance, there should still be much professional technology formed with much effort to be imparted to the young people.

About the afore-mentioned punch press and laser cutting, when we blindly seek the stamping process and laser material processing, there will be dimension deviation*1 required by design on the drawing. Therefore, it is a kind of very profound knowledge in the manufacturing industry that the processing is carried on after fully considering requirements of the process so as to balance the product whole. In the past, it was finished only by the craftsman himself from punch press processing to ""saw"" cutting till finally manual processing.

Only through overlooking the whole situation from perception to ensure dimension, can the balance of the product as a whole be achieved. Similarly, it is also essential that the design be carried out after considering how clients use the product through imagination. Just like the current electric automobile driving on the street, it needs a precision sheet metal with permissible deviation 1/100 mm to be processed, so its dimension is confirmed through the microscope. What's more, not only the dimension is required within the tolerance limits, but also it is required to work normally when the Only through overlooking the whole situation from perception to ensure dimension, can the balance of the product as a whole be achieved. Similarly, it is also essential that the design be carried out after considering how clients use the product through imagination. Just like the current electric automobile driving on the street, it needs a precision sheet metal with permissible deviation 1/100 mm to be processed, so its dimension is confirmed through the microscope. What's more, not only the dimension is required within the tolerance limits, but also it is required to work normally when the clients are using it, so it needs such kind of quality that can be seen and touched.

In order to achieve high level of quality, Asano has publicized 50 items of ""Quality Troubles in the past”*2. There are several hundred cases of ""Quality Troubles in the past"" in Hara's mind. He can judge quality of the components and parts even without checking the dimension. It's never too much to describe his memory as human brain computer and he uses such memory to confirm that whether it is done fully according to the drawing", and at the same time, he even imagines how clients use such product together with other components in his mind.

Of course, his such implicit consciousness works before processing. For example, the welding part is easy to deform, and he always presupposes such thing and then begins processing.

Sanwa factory where Hara is has the habit of double confirmation. First, it is to prevent the mistakes made from busy work; second, it is for the young people to inherit the profound knowledge of quality assurance. Only through communication between generation and generation, can the quality assurance in Asano be passed from generation to generation.

There are some other examples about Hara's imparting to young people. The ""welding"" activity in Sanwa factory is such an example. In order to judge the quality of appearance of the welding part, he shows the picture of appearance sample of the welding part on the storage rack. In this way, the young people can judge the quality according to every pattern and every material at one glance.

About ninety employees in the manufacturing department and the headquarter as well as in Sanwa factory will hold a learning meeting regularly in the dining hall. People with different background from assembly part*3 oriented Sanwa factory and steel skeleton oriented headquarter will get together and impart the wisdom of quality assurance department to all the staff through holding drawing-understanding contest.

Hara keeps trying to make implicit knowledge visible for it to be spread among different departments and among different ages of the company and build quality assurance of Asano into "Well done is deserved for a department.